Michael J. Turkovich MS, Linda van Roosmalen PhD, Douglas A. Hobson PhD, and Erik A. Porach BS

Rehabilitation Engineering Research Center on Wheelchair Transportation Safety, Department of Rehabilitation Science and Technology, University of Pittsburgh, Pittsburgh, PA

ABSTRACT

The securement effectiveness and opinions of wheelchair users were obtained and compared for a prototype auto-docking, a prototype rear-facing wheelchair passenger station, and a four-point, strap-type tiedown system that were installed in a large accessible transit vehicle. The systems were tested for emergency driving and normal vehicle operation over a 20-minute route in downtown Pittsburgh, while measuring wheelchair movement and vehicle accelerations. All securement systems complied with the ADA maximum displacement limit of 50 mm and all vehicle accelerations remained below 1 g. Overall, subjects preferred the automated docking and rear-facing wheelchair passenger stations to the four-point tiedown system, but expressed concerns about traveling facing rearward and adding an extra bracket to the wheelchair for auto-docking securement.

Key Words:

wheelchair securement, large accessible transit vehicles, transportation safety, transportation independence, public transportation

INTRODUCTION

The Americans with Disabilities Act (ADA) requires that public transportation is accessible to all individuals (1). Public transportation vehicles are also required to provide wheelchair tiedown and occupant restraint system (WTORS) for use by individuals who remain seated in their wheelchair during travel, facing either forward or rearward in the vehicle. In addition to complying with certain strength requirements that are based on vehicle size, wheelchair securement systems must be designed to limit the movement of occupied wheelchairs to less than 50 mm (2 in) during normal vehicle operating conditions (1). Compared to small vehicles such as vans or mini-vans where moderate-to-severe crash events are a significant concern and crash accelerations frequently exceed 20 g, large intra-city buses that provide access to people seated in wheelchairs, often referred to as large accessible transit vehicles or LATVs, are considered “low-g environment” vehicles. This is because the combination of large vehicle size and relatively low travel speeds on urban streets leads to a very low likelihood of these vehicles being involved in collisions of any significant magnitude. In a study by Blower et al. (2005), data for police accident reports of transit bus crashes in Florida over a two year period were used to estimate that transit buses are involved in a collision of 5 g or greater every 27 million vehicle miles traveled and are involved in a crash of 10 g or greater every 455 million miles traveled (2). These involvement rates are 16 to 250 times less than those for passenger cars for greater than 5 mph and greater than 10 mph crashes, respectively (unpublished data).

Given this low-g environment, it is not uncommon for people to travel in LATVs while standing and using handholds to stabilize their position in the vehicle during stopping, turning, and acceleration. In this regard Zaworski et al. (2007) reported LATV accelerations that averaged 0.2 g, and accelerations rarely exceed 0.4 g during normal driving conditions. During emergency maneuvers, accelerations averaged 0.4 g and sometimes reached as high as 0.8 g during hard braking (3).

At the present time, the most common way to secure wheelchairs in LATVs in accordance with transportation guidelines of the ADA is by means of a four-point strap-type tiedown. Although this is a very effective way to secure a wide range of wheelchairs in public transportation, especially in smaller vehicles where the likelihood of moderate to severe crashes are relatively high, it is also a method that requires significant time and effort by the vehicle driver to be implemented properly (4). This is especially true for wheelchairs that do not provide easily accessible securement points in accordance with ANSI/RESNA WC19 Wheelchairs for Use as Seats in Motor Vehicles (5). As a result, occupied wheelchairs in LATVs are often not secured using all four tiedown straps or they may not be secured at all. It is therefore not surprising that injuries to wheelchair users in public transportation have been shown to result from misuse, or lack of use, of four-point, strap-type tiedowns (6).

When considering the low-g environments of large slow moving intra-city vehicles in which some passengers may stand during vehicle movement, alternative methods to universal wheelchair securement or containment may offer a reasonable level of transportation safety to wheelchair-seated passengers (7), while also offering greater independence and compatibility with operational issues, such as bus schedules.

STUDY OVERVIEW AND OBJECTIVES

Based on the issues and concerns noted above about issues regarding four-point tiedowns in LATVs, a research study was conducted to investigate the use of alternative wheelchair securement methods that will offer greater independence to people who travel while seated in their wheelchairs, and be more compatible with transportation operational demands, while still offering an acceptable level of transportation safety. These alternative securement systems included a rear-facing wheelchair passenger station (RF-WPS) and an auto-docking securement system using the universal docking interface geometry (UDIG) as specified in Annex A of ISO 10542-3 Wheelchair Tiedown and Occupant Restraint Systems – Part 3: Docking-Type Tiedown Systems(8).

The primary objective of this study was to assess wheelchair-user and LATV driver experiences and opinions regarding these two alternative and user-independent methods of wheelchair securement in LATVs and to compare these experiences and opinions to those with the four-point, strap-type tiedown method of wheelchair securement. A secondary objective was to measure and/or monitor wheelchair movement and vehicle accelerations during normal vehicle operation and emergency vehicle maneuvers for these three methods of securement, and to compare wheelchair movements during normal vehicle operation to the maximum movements allowed by ADA. This paper provides preliminary information on wheelchair user responses to the three systems, on vehicle accelerations during normal and emergency driving on typical city streets, and compares peak wheelchair displacements during normal and emergency vehicle travel using the three securement methods to the maximum displacement of 50 mm allowed by ADA.

METHODS

Figure 1. a) manual wheelchair secured by 4-point strap-type tiedown; b) top view of UDIG auto docking system; c) powered wheelchair in rear-facing passenger station (RF-WPS) (Click for larger view)

Figure 1. a) manual wheelchair secured by 4-point strap-type tiedown; b) top view of UDIG auto docking system; c) powered wheelchair in rear-facing passenger station (RF-WPS) (Click for larger view) The three wheelchair securement systems were installed in an LATV that is currently used in the city of Pittsburgh, PA. As shown in Figure 1, these systems included a retractor-based 4-point tiedown system, a prototype UDIG auto-docking system, and a prototype rear-facing wheelchair passenger station (RF-WPS). Unlike RF-WPS used in LATVs today, the prototype system in these tests includes pneumatically powered but load-limited “arms” that move inward and grip the wheelchair by means of padded surfaces after it is backed into position against a forward barrier, thereby providing a semi-automatic means to resist rearward movement of the wheelchair during vehicle accelerations. Activation of this gripping system is under the control of the wheelchair user by means of a wall switch.

The securement systems were first tested under emergency and normal driving conditions with a 50th percentile ISO 7176-11 (9 test dummy in a manual wheelchair, a powered wheelchair, and a three-wheeled scooter wheelchair. All of these wheelchairs were equipped with WC19 securement points as well as UDIG adaptors. Each wheelchair was also equipped with a wheelchair-anchored pelvic belt to which a vehicle-anchored shoulder belt could be connected in accordance with WC19 requirements.

Figure 2. Wheelchair-mounted spring-loaded pens and floor targets for recording displacement of wheelchairs during LATV normal and emergency driving conditions. (Click for larger view)

Emergency driving conditions consisted of hard braking from 20 mph to 0 mph, and turning on a 15.2 m radius (50-foot radius) while traveling at 33 kph (20 mph) (10). As shown in Figure 2, maximum wheelchair displacement was measured by means of a spring-loaded pen attached to the front of each wheelchair such that the pen was located at and contacted the center of a 50-cm (2-in) diameter circle after securement of the wheelchair in each station and prior to vehicle movement. Maximum displacement of each wheelchair following each emergency maneuver was compared to the ADA maximum allowed displacement during normal vehicle travel of 50 mm (2 in). An accelerometer was attached to the vehicle floor on the centerline, and just rear of the 4 point strap-style tiedown station to record vehicle accelerations during all tests. Acceleration data were collected at 100 Hz and filtered as described in SAE J2181 (11).

After completing the wheelchair-displacement tests during emergency conditions, twenty wheelchair users were testeda . Each subject was assigned to one of the three wheelchairs, based on the current type of wheelchair they used (i.e. manual, power, or scooter) and subjects were tested in groups of three corresponding to the three wheelchair stations. Every subject was tested in three trials using a different wheelchair securement station in each trial. All testing was conducted in one LATV but seven different drivers were used for testing the different groups of subjects. Testing consisted of boarding the bus, entering the wheelchair station, securing the wheelchair (or having the wheelchair secured by the driver in the case of the four-point tiedown), and traveling in the LATV for a 20-minute ride over a prescribed route in downtown Pittsburgh. The route included city driving with multiple turns, braking, and uphill and downhill sections. Participants were required to use the wheelchair-anchored pelvic belt during the trials but use of a vehicle-anchored shoulder belt was optional. After completion of each drive, subjects were asked to respond to a series of questions regarding the usability, independence, safety, and their likes and dislikes, as well as to provide any suggestions for improving the securement system just used.

RESULTS

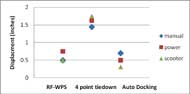

Figure 3. Peak displacement of each wheelchair type in each securement system during emergency testing. (Click for larger view)

Each securement station complied with the ADA displacement requirement in that the maximum displacement of all wheelchairs remained below the ADA 50-mm limit, even during emergency driving conditions. The peak wheelchair displacements for each wheelchair, and each securement station are shown in Figure 3. On average, the peak displacements were lowest for the auto-docking and RF-WPS stations and greatest for the four-point tiedown system.

All vehicle accelerations recorded during emergency and normal driving were less than 1 g. The maximum resultant acceleration during normal driving was 0.6 g. The maximum acceleration during emergency braking was 0.69 g in the forward direction. The maximum lateral acceleration during high-speed turning was 0.46 g.

Results of the subject surveys indicate that, overall, wheelchair users felt safe and secure in all three securement systems. On aspects of usability and user independence, the auto docking and RF-WPS systems received more positive comments than the four-point tiedown system because they were easier to use, required little or no driver assistance, and would have the least effect on the bus schedule. However, some subjects disliked that fact that they were seated rear facing in the RF-WPS, and they did not like the additional UDIG adaptive hardware added to their wheelchair.

DISCUSSION AND CONCLUSIONS

All three securement systems met the ADA requirements for maximum displacement during normal vehicle travel of less than 50-mm movement in any direction, but the 4-point tiedown allowed the highest wheelchair displacements. This may be due variability in manual tensioning of the tiedown straps for the seven drivers, as each person may perceive “tight and secure” differently. Additional analysis of the displacement data will be performed to explore this possibility.

Preliminary review of results from the surveys of the twenty wheelchair users indicate that the auto docking and RF-WPS are generally perceived as safe, easy to use, and offer the greatest independence in traveling on LATVs. However user concerns that need to be addressed include dislike for traveling facing rearward and the additional adaptive bracket on the wheelchair needed for auto-docking securement. The results of this study therefore point to the need for new securement systems that target the low-g LATV environment, but that allow wheelchair passengers to travel with a reasonable level of safety and greater independence facing forward facing without additional hardware added to their wheelchair. Additionally, easy-to-use vehicle-anchored occupant restraint systems for use in a low-g environment need to be explored.

a The test protocol and written informed-consent procedures for this study were approved by a properly constituted institutional review board at the University of Pittsburgh.

REFERENCES

- Americans with Disabilities Act (ADA). (1990). Pub. L. 101-366 USC Sections 12101. Washington, DC.

- Blower, D., Woodrooffe, J., and Schneider, L.W. (2005) Characterization of Transit-Bus Accidents Resulting in Passenger Injuries for Use in Developing Alternative Methods for Transporting Wheelchair-Seated Travelers. Proceedings of the 2005 International Truck & Bus Safety & Security Symposium

- Zaworski, U., Hunter-Zaworski, K., & Baldwin, M. (2007). Bus dynamics for mobility-aid securement design. Assistive Technology, 19, 200-209.

- Shaw, G., and Gillespie, T. (2003). Appropriate protection for wheelchair riders on public transportation on public transit buses. Journal of Rehabilitation Research and Development, 40, 309-320.

- American National Standards Institute, Section 19, Volume 1 Wheelchair Standards, Wheelchair Used a Seats in Motor Vehicles, May 2000 Rehabilitation Engineering an Assistive Technology Society of North America, Arlington, Virginia.

- Shaw, G. (2000). Wheelchair rider risk in motor vehicles: A technical note. Journal of Rehabilitation Research and Development, 37(1), 89-100.

- Hobson, D., & van Roosmalen, L. (2007). Towards the next generation of wheelchair securement-development of a demonstration UDIG-compatible wheelchair docking device. Assistive Technology, 19 (4), 210-222.

- ISO. (2005). 10542-3: Technical systems and aids for disabled or handicapped persons-Wheelchair tiedown and occupant-restraint systems- Part 3: Docking type tiedown systems (Standard). Geneva, Switzerland.

- ISO. (1992). 7176-11: Wheelchairs- Part 11:Test Dummies (Standard). Geneva, Switzerland.

- Mercer, P.W., & Billing, J.R. (1990). Assessment of a transportable mobility aid in severe driving conditions- An exploratory test (No. CV-90-03). Toronto, Ontario, Canada: Vehicle Technology Office.

- SAE. (1993). J2181: Steady-State Circular Test Procedure for Trucks and Buses. Warrendale, Pa.

ACKNOWLEDGMENTS

This project was funded by the Rehabilitation Engineering Research Center on Wheelchair

Transportation Safety, Grant #H133E010302 from the National Institute on Disability and

Rehabilitation Research, U.S. Department of Education. The authors thank the Pittsburgh Port Authority for lending their vehicle and assisting with securement system installation and Q’Straint, Sure-Lock, BodyPoint, MyAmigo, Invacare Corp. and Sunrise Medical for providing securement technologies, seat belts, and wheelchairs for use in this study.

Michael Turkovich, Rehabilitation Engineering Research Center on Wheelchair Transportation Safety, Department of Rehabilitation Science and Technology, University of Pittsburgh,

2310 Jane St, Suite 1300, Pittsburgh, Pa 15203

Email: mjt52@pitt.edu